产品分类

- RO water treatment equipment

- Fruit and vegetable cleaning equipment

- To nuclear, crushing equipment

- Preheat, inactivate enzyme equipment

- Beating and pressing equipment

- Beverage pre-processing and blending equipment

- CIP cleaning system

- UHT tube sterilization equipment, plate sterilization

- Empty tank decanting, solid tank stacker

- Filling and sealing machine (without gas)

- Beer can filling and sealing machine

- Thick sauce filling and sealing machine series

- Automatic PET filling and capping machine

- PE filling machine, aluminum foil sealing machine

- Glass bottle filling and capping machine

- Liquid nitrogen filling machine, liquid nitrogen freezing tunnel

- Vacuum inspection, liquid level inspection equipment

- Sterilization pot, tunnel spray sterilization

- (granular) solid canister series

- High speed blow dryer, can oiling machine

- Automatic basket loading and unloading basket machine series

- Marking machine, labeling machine, labeling machine

- Packing machine, heat shrink film machine

- other devices

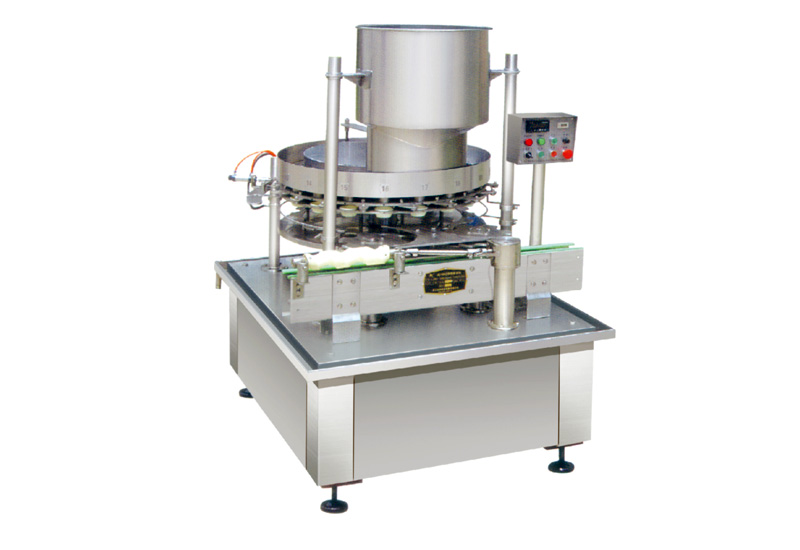

Particle filling machine DP18KG

2018-5-4 11:49:46

This machine is specially designed for the quantitative filling of mixed materials, and it is also suitable for the quantitative filling of single materials. Automatic control for all blanking, no can no blanking. All with the touch screen to adjust the speed, filling capacity, is the first equipment of the famous eight-treasure porridge production plant.

Main technical parameters:

Materials :95%

stainless steel, 5% carbon steel (foundation)

Number of filling head: 18

Production type: Chinese porridge, soup

Production capacity: 100~250 cans/min

Applicable tank diameter: 52.3 ~ 83.3 mm Φ Φ

Applicable tank height: 100~250mm

Power: 1.5 KW

Overall dimensions: 1200 x 1400 x 1800mm

Weight: 1.2 T