- RO water treatment equipment

- Fruit and vegetable cleaning equipment

- To nuclear, crushing equipment

- Preheat, inactivate enzyme equipment

- Beating and pressing equipment

- Beverage pre-processing and blending equipment

- CIP cleaning system

- UHT tube sterilization equipment, plate sterilization

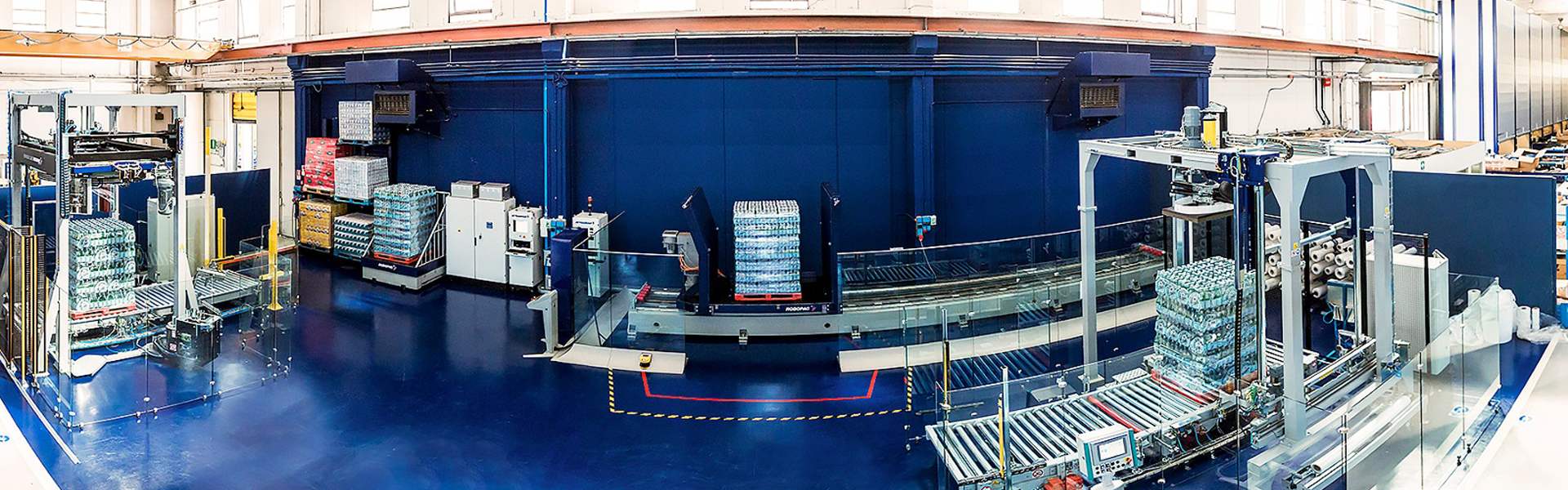

- Empty tank decanting, solid tank stacker

- Filling and sealing machine (without gas)

- Beer can filling and sealing machine

- Thick sauce filling and sealing machine series

- Automatic PET filling and capping machine

- PE filling machine, aluminum foil sealing machine

- Glass bottle filling and capping machine

- Liquid nitrogen filling machine, liquid nitrogen freezing tunnel

- Vacuum inspection, liquid level inspection equipment

- Sterilization pot, tunnel spray sterilization

- (granular) solid canister series

- High speed blow dryer, can oiling machine

- Automatic basket loading and unloading basket machine series

- Marking machine, labeling machine, labeling machine

- Packing machine, heat shrink film machine

- other devices

UY400 (cans) automatic oiling machine

2018-5-4 12:02:01

After sealing the two ends of tinplate cans, the outer surface of the sealing line made of tinplate material will cause friction between the cans and damage to the surface coating due to the turbulence in the long-distance transportation. In addition, in the process of empty tank and solid tank sealing, if the sealing wheel surface of the tank sealing machine is not repaired and replaced in time after wear, the coating on the surface of the tank cover will also be damaged. When the above two situations occur, when the tin can through sterilization after the sealing line surface is easy to rust, in order to prevent this phenomenon, need to tinplate sealing line online automatic oiling, forming a protective film, make the sealing line always bright as new, in order to improve the appearance of the product.