- RO water treatment equipment

- Fruit and vegetable cleaning equipment

- To nuclear, crushing equipment

- Preheat, inactivate enzyme equipment

- Beating and pressing equipment

- Beverage pre-processing and blending equipment

- CIP cleaning system

- UHT tube sterilization equipment, plate sterilization

- Empty tank decanting, solid tank stacker

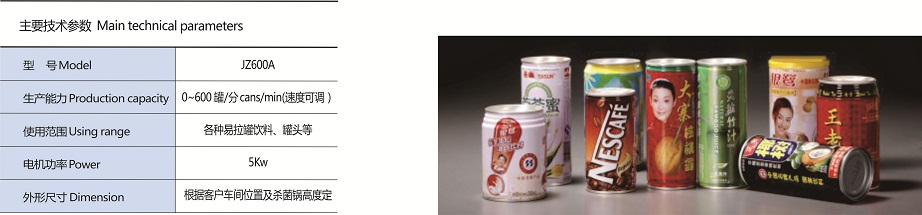

- Filling and sealing machine (without gas)

- Beer can filling and sealing machine

- Thick sauce filling and sealing machine series

- Automatic PET filling and capping machine

- PE filling machine, aluminum foil sealing machine

- Glass bottle filling and capping machine

- Liquid nitrogen filling machine, liquid nitrogen freezing tunnel

- Vacuum inspection, liquid level inspection equipment

- Sterilization pot, tunnel spray sterilization

- (granular) solid canister series

- High speed blow dryer, can oiling machine

- Automatic basket loading and unloading basket machine series

- Marking machine, labeling machine, labeling machine

- Packing machine, heat shrink film machine

- other devices

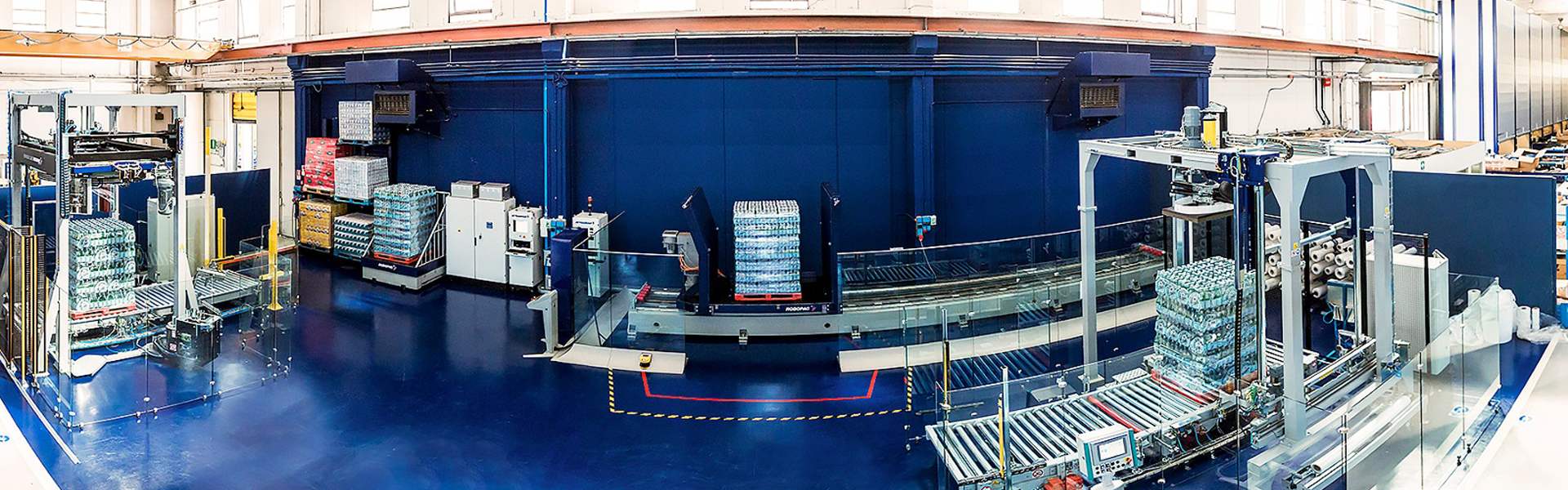

Automatic loading basket and unloading cage unit DP600A

2018-5-4 12:37:00

This machine is mainly used for automatic caging of canned drinks or canned food before secondary sterilization.

Through the chain closed tank platform and real tank after tank device will finish filling sealing is automatically loaded layer at the bottom of pile in sterilization cage (basket), rail transport system through the electric car circulation again sent to sterilization sterilization pot, the whole process of loading cage board automatic release, automatic rise, automatic tank, canning, automatic fall, cage full automatic stop canning, replace tooling cage way, save manpower, greatly improve production efficiency

Automatic loading and unloading cage system is the guarantee to realize the continuous and efficient work of the whole post-sterilization system, which is mainly composed of automatic loading system, trolley system and automatic unloading cage system.

1) automatic cage loading system

This system function: first, the trolley will send the cage frame to the cage loading station under the cage host. The hydraulic lifting platform will raise the cage frame bottom plate to the height of the cage conveying line (the position of the bottom plate should be lower than the cage conveying line, and a separator should be placed on the bottom plate). The automatic suction and release separator will place a separator above the bottom plate.

The bottle conveying line sends the product to the cage conveying line. The product is divided into one layer by one through the bottle pressing device. The bottle carrying mechanism holds the separated whole layer of the product and sends it to the cage partition.

This system is controlled automatically by PLC, which saves manpower and greatly improves production efficiency.

2) automatic suction and release separator

The main frame of this mechanism is placed on the upper part of the cage main machine and the cage main machine. The clamping device of the suction separator reciprocates and generates the negative pressure automatic suction and discharge separator through the vacuum generator.

3) automatic cage unloading system

This system function: the first car will full box products sent to cage under the host of cage unload station, hydraulic lifting platform rises a layer of products, holding bottle transfer institutions hold a whole layer products sent to the discharge cage conveyor line, automatic suction clapboard institutions will suck a clapboard is placed in a baffle plate piled up lifting mechanism, hydraulic lifting platform down a layer height, repeat the cycle until the whole box product finish unloading, discharge conveyors will products sent to lose bottle cage online for secondary packaging.

This system is controlled automatically by PLC, which saves manpower and greatly improves production efficiency.

4) clapboard stacking lifting mechanism

This system is used to collect the diaphragm and cooperate with the absorber mechanism to realize the circulation of the diaphragm.