- RO water treatment equipment

- Fruit and vegetable cleaning equipment

- To nuclear, crushing equipment

- Preheat, inactivate enzyme equipment

- Beating and pressing equipment

- Beverage pre-processing and blending equipment

- CIP cleaning system

- UHT tube sterilization equipment, plate sterilization

- Empty tank decanting, solid tank stacker

- Filling and sealing machine (without gas)

- Beer can filling and sealing machine

- Thick sauce filling and sealing machine series

- Automatic PET filling and capping machine

- PE filling machine, aluminum foil sealing machine

- Glass bottle filling and capping machine

- Liquid nitrogen filling machine, liquid nitrogen freezing tunnel

- Vacuum inspection, liquid level inspection equipment

- Sterilization pot, tunnel spray sterilization

- (granular) solid canister series

- High speed blow dryer, can oiling machine

- Automatic basket loading and unloading basket machine series

- Marking machine, labeling machine, labeling machine

- Packing machine, heat shrink film machine

- other devices

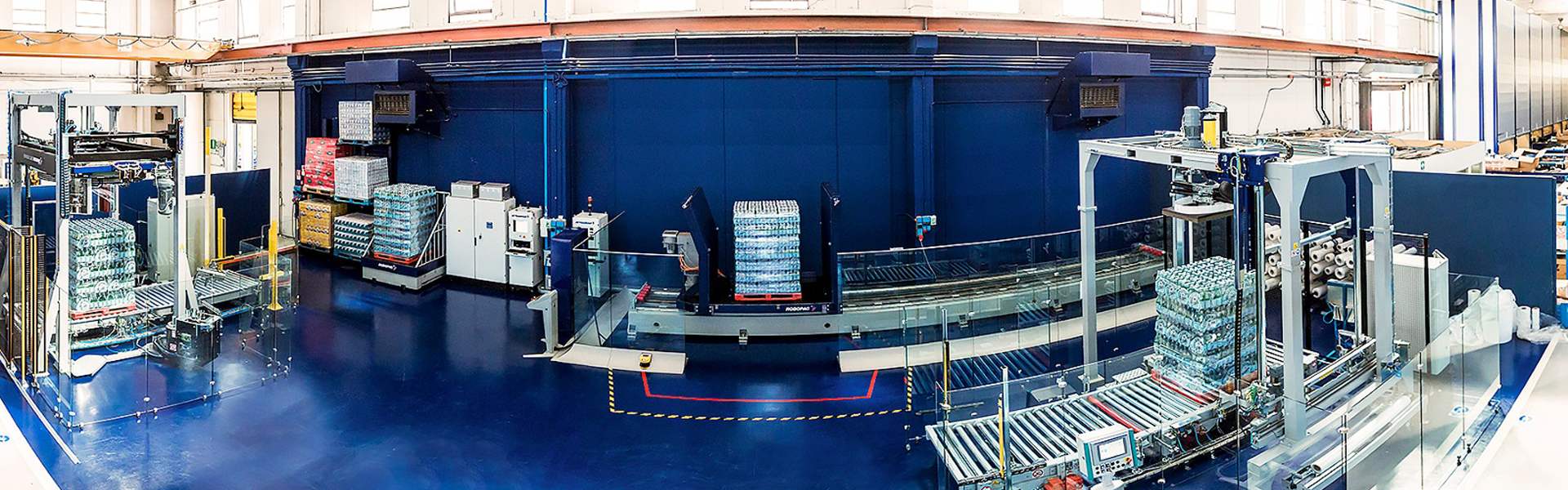

Automatic shrink film packaging machine DP-FPM/12F

2018-5-4 14:00:32Technical Characteristics

DP-FPM/12F is an automatic, automatic and unmanned economic side packaging machine developed by our company. It is widely used in mass production and packaging of the flow operation, automatic feeding, transportation, bag entry, sealing and contraction. High efficiency and suitable for different height and width of the products.

1. the sealing section of the transverse blade is driven by the vertical type, the longitudinal knife adopts the international advanced thermostat side sealing knife, the sealing line is straight and firm, and the sealing line can be ensured in the middle position of the product to achieve the perfect sealing effect.

2. The constant temperature heating and sealing system can be used to seal and shrink the shrinkable films of various industrial standards such as POF. Products with different package sizes can be completed only by hand wheel adjustment, increasing reliability and making it

easier to operate.

3, longitudinal sealing knife continuous cutting action, product length is not limited.

4, the machine adopts the most advanced PLC programmable controller, with safety protection and alarm device, and the sealing and cutting system can make the sealing action continuously and smoothly, without replacement, the maintenance operation is very simple.

5. Feeding length control is combined with electric eye detection and timer to control the length of the film accurately, so that the shrinkage effect can be controlled more easily.

6. Add two sets of electric eye in horizontal and vertical electric eye to facilitate switching selection. For thin or small package, seal packaging can be done easily.

7. Automatic coiling waste is controlled by a single motor. It will not be too loose or too tight.

8, according to customer needs, add automatic blowing function

9. According to the needs, the front power feeding line and the rear end.

Type no. DP-FPM/12F

The input power:(TN-S)22KWKW

Production speed:12case/min

Belt width: φ28mm-φ125mm

Sealing and cutting time: accounting temperature

The air consumption :0.5m³/min

Air pressure: 0.6~0.8Mpa

Thermal shrinkage channel size: L1800mmxW650mmxH450mm

Maximum package size: L420mm x W300mmxH350mm

Machine dimension: L6000mmxW3200mmxH2100mm