- RO water treatment equipment

- Fruit and vegetable cleaning equipment

- To nuclear, crushing equipment

- Preheat, inactivate enzyme equipment

- Beating and pressing equipment

- Beverage pre-processing and blending equipment

- CIP cleaning system

- UHT tube sterilization equipment, plate sterilization

- Empty tank decanting, solid tank stacker

- Filling and sealing machine (without gas)

- Beer can filling and sealing machine

- Thick sauce filling and sealing machine series

- Automatic PET filling and capping machine

- PE filling machine, aluminum foil sealing machine

- Glass bottle filling and capping machine

- Liquid nitrogen filling machine, liquid nitrogen freezing tunnel

- Vacuum inspection, liquid level inspection equipment

- Sterilization pot, tunnel spray sterilization

- (granular) solid canister series

- High speed blow dryer, can oiling machine

- Automatic basket loading and unloading basket machine series

- Marking machine, labeling machine, labeling machine

- Packing machine, heat shrink film machine

- other devices

Bucket type pre-boiler

2018-1-3 13:41:33

- Detailed introduction

| Type | precooker |

| Power | 1.5KW |

| Size | 10500×850×2200mm |

| USED | Preboil, blanch and blanch |

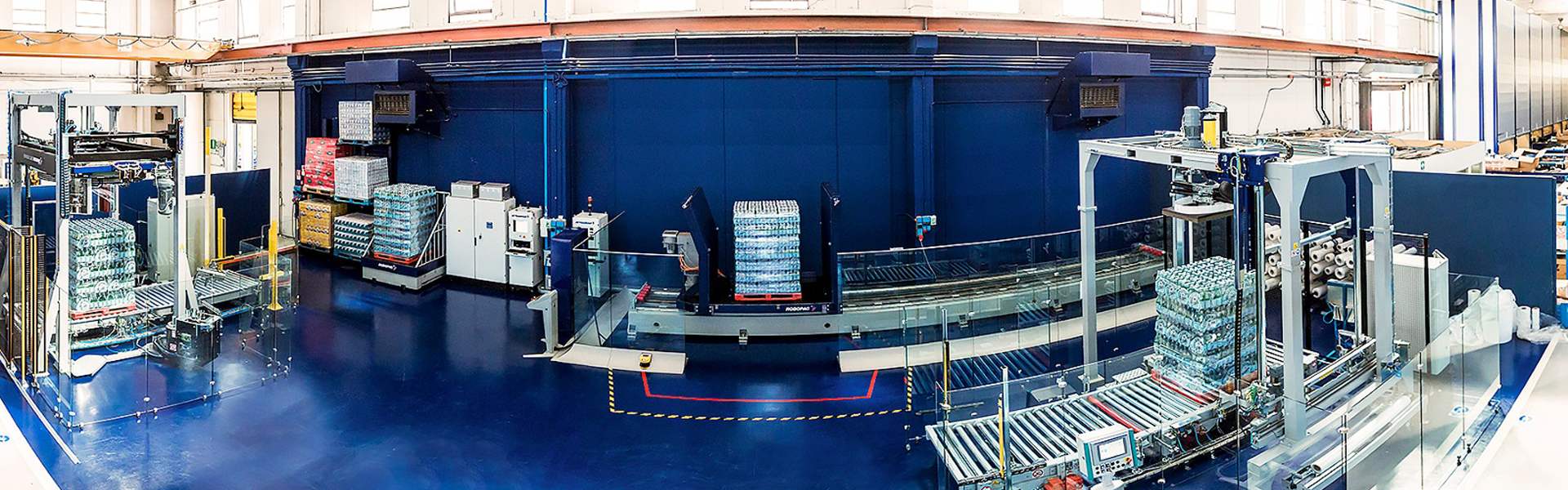

Product performance and characteristics: rest assured series sterilization, cooling machine is the absorption of foreign advanced technology, combined with domestic food, beverage, pharmaceutical and other industries, the current production process needs to develop a successful set of sterilization, cooling and integration of new products.

The series of sterilization, cooling machine made of high quality stainless steel, advanced control instruments, beautiful shape.

Manipulator maintenance is convenient wait for a characteristic, compared with the current (pool) sterilization method the labor intensity is low, less manpower, high mineralization degree of automatic control and temperature automatic control can be within 98 °, the lower water temperature difference is small, easy to control product quality, this product is completely symbol of GMP, HACCP certification requirements, high rate of health, is the ideal equipment of vegetable food processing industry.

Working principle: in food, beverage, pharmaceutical and other industries, it is required to sterilize some packaged products by water bath.

The products of the knapsack family are placed on the stainless steel mesh belt with adjustable speed. After entering into the sterilization in sequence under the action of the conveyor belt, the conveyor belt is brought into the cooling box for uniform cooling, so as to meet the sterilization requirements of the product.

This series of equipment runs continuously, and the sterilized packaging products are continuously sent to the next production process