- RO water treatment equipment

- Fruit and vegetable cleaning equipment

- To nuclear, crushing equipment

- Preheat, inactivate enzyme equipment

- Beating and pressing equipment

- Beverage pre-processing and blending equipment

- CIP cleaning system

- UHT tube sterilization equipment, plate sterilization

- Empty tank decanting, solid tank stacker

- Filling and sealing machine (without gas)

- Beer can filling and sealing machine

- Thick sauce filling and sealing machine series

- Automatic PET filling and capping machine

- PE filling machine, aluminum foil sealing machine

- Glass bottle filling and capping machine

- Liquid nitrogen filling machine, liquid nitrogen freezing tunnel

- Vacuum inspection, liquid level inspection equipment

- Sterilization pot, tunnel spray sterilization

- (granular) solid canister series

- High speed blow dryer, can oiling machine

- Automatic basket loading and unloading basket machine series

- Marking machine, labeling machine, labeling machine

- Packing machine, heat shrink film machine

- other devices

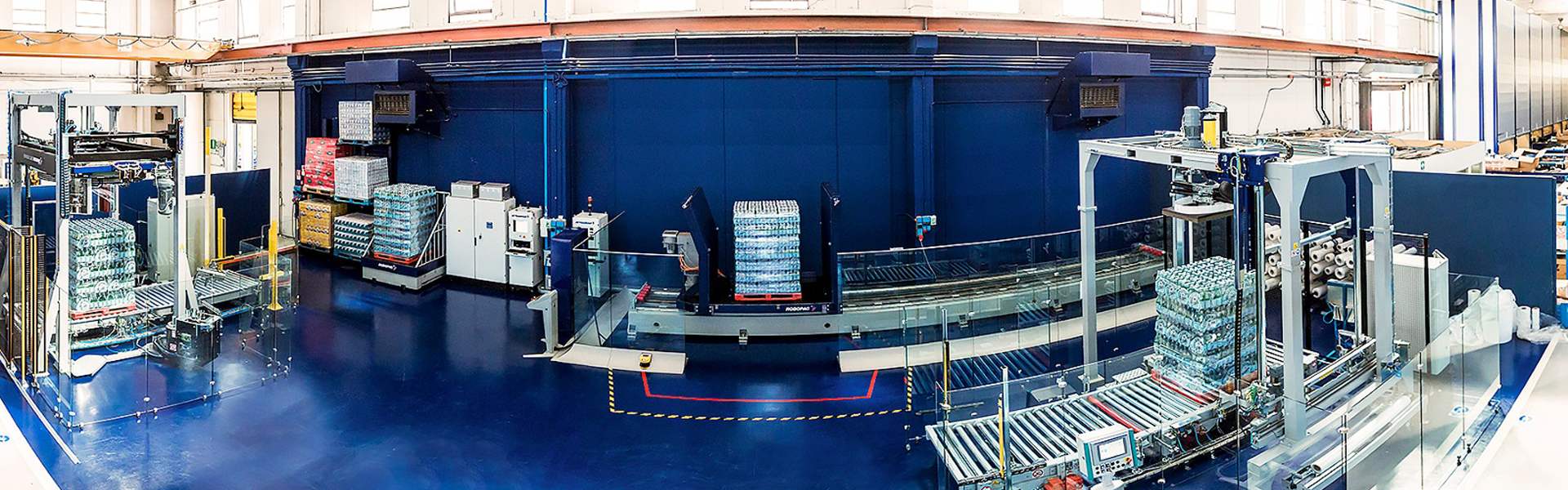

Split type CIP cleaning system

2018-1-3 13:58:57

Performance characteristics:

(1) flexible, general: the system can be carried out separately pickling, alkali washing, hot water washing and other processes, but also according to the need to prepare specific cleaning procedures for automatic cleaning;

Not only can effectively clean the equipment, but also can control the growth of microorganisms;

At the same time according to customer requirements can be configured semi-automatic, automatic and control systems.

Safe and reliable: concentrated acid, concentrated alkali solution in the buried type concentrated acid, concentrated alkali cylinder;

Tank level automatic control and overflow protection system;

The unique discharge port structure can prevent the crystallization of cleaning liquid from blocking the pipeline.

(3) economic, reliable: compared with manual cleaning, greatly reduce the cleaning time, improve work efficiency;

The use of cleaning agents and water will be more scientific and reasonable;

At the same time, the steam consumption is relatively small, which can achieve the purpose of rational use of energy.

So effectively reduce the cost of cleaning.

Mature PLC control system: many years of experience, so that our procedures are more perfect, coupled with imported quality control components, can ensure the system long-term, stable work;

Friendly man-machine interface can shorten the training time of operators and visually display the working status of key parts of equipment.

The easy-to-understand help interface can assist operators to judge and deal with a variety of common fault information, so that the equipment can be restored to the normal state in a timely manner.