- RO water treatment equipment

- Fruit and vegetable cleaning equipment

- To nuclear, crushing equipment

- Preheat, inactivate enzyme equipment

- Beating and pressing equipment

- Beverage pre-processing and blending equipment

- CIP cleaning system

- UHT tube sterilization equipment, plate sterilization

- Empty tank decanting, solid tank stacker

- Filling and sealing machine (without gas)

- Beer can filling and sealing machine

- Thick sauce filling and sealing machine series

- Automatic PET filling and capping machine

- PE filling machine, aluminum foil sealing machine

- Glass bottle filling and capping machine

- Liquid nitrogen filling machine, liquid nitrogen freezing tunnel

- Vacuum inspection, liquid level inspection equipment

- Sterilization pot, tunnel spray sterilization

- (granular) solid canister series

- High speed blow dryer, can oiling machine

- Automatic basket loading and unloading basket machine series

- Marking machine, labeling machine, labeling machine

- Packing machine, heat shrink film machine

- other devices

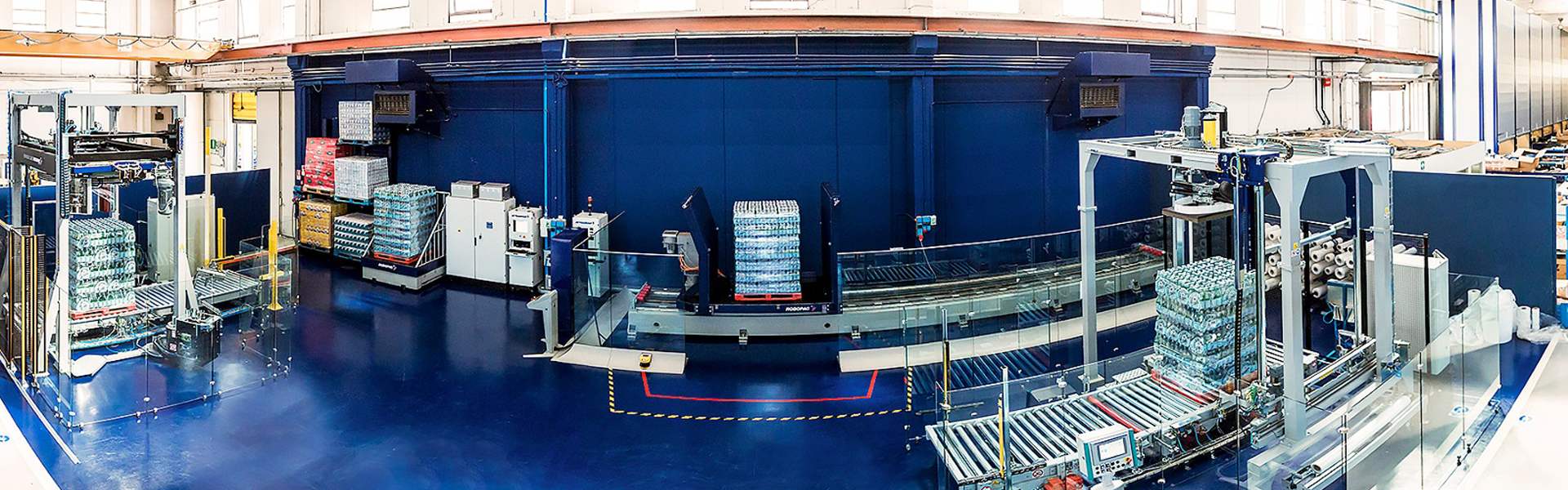

Tubular ultra-high temperature sterilization machine

2018-1-3 13:59:16

Tubular UHT sterilizer is widely used in the automatic system of "aseptic" and "non-aseptic" heat treatment of liquid food.

The company of the UHT sterilization machine series production capacity can be from 1 to 30 t/h, typical sterilization temperature is 90 ~ 140 ℃, can connect any filling machine (or other types of sterile), the sterilization machine and control system installed on the chassis, control components adopt international famous brand products, including PLC program controller and industrial control screen, steam pressure and regulating valve, shunt valve, regulator valve, pump, hot water pump.

All other valves and pipe fittings are of high quality and reliable.

This sterilizer is designed for high precision product/water temperature difference control.

Products from the balance tank pump, preheat to homogeneous temperature, preheat to 90 ~ 95 ℃, the stability of milk protein, and ultra high temperature sterilization, filling finally cooled to the temperature.

The system USES hot water for presterilization in the circulation loop to save energy.

The diameter, shape (flat or corrugated) of the tube and the choice of tube bundle are determined by the needs of the product.

Each heat exchanger needs only 4 o-gaskets (only at the medium end) and only one inspection per year.

Can choose to hot filling, such as 90 ℃.

Economic processing means, can be used semi-automatic unit, also get the same effect.

Sterilization soya-bean milk cooling water 25℃

: The 65 ℃ homogeneous - 135 ℃ for 15 s - 28 ℃

●Juice, tea drinks

30~75℃→140℃(4S、10S、15S)→85~92℃→(40℃)backflow

cooling water1:2 ≤ 30℃(standby application)

●sterilized milk

5℃→65℃homogeneity→95℃ 30S→140℃ 4S→25℃

ice water1:1 (≤2℃standby application) Cooling water 1:1 (30 ℃)