|

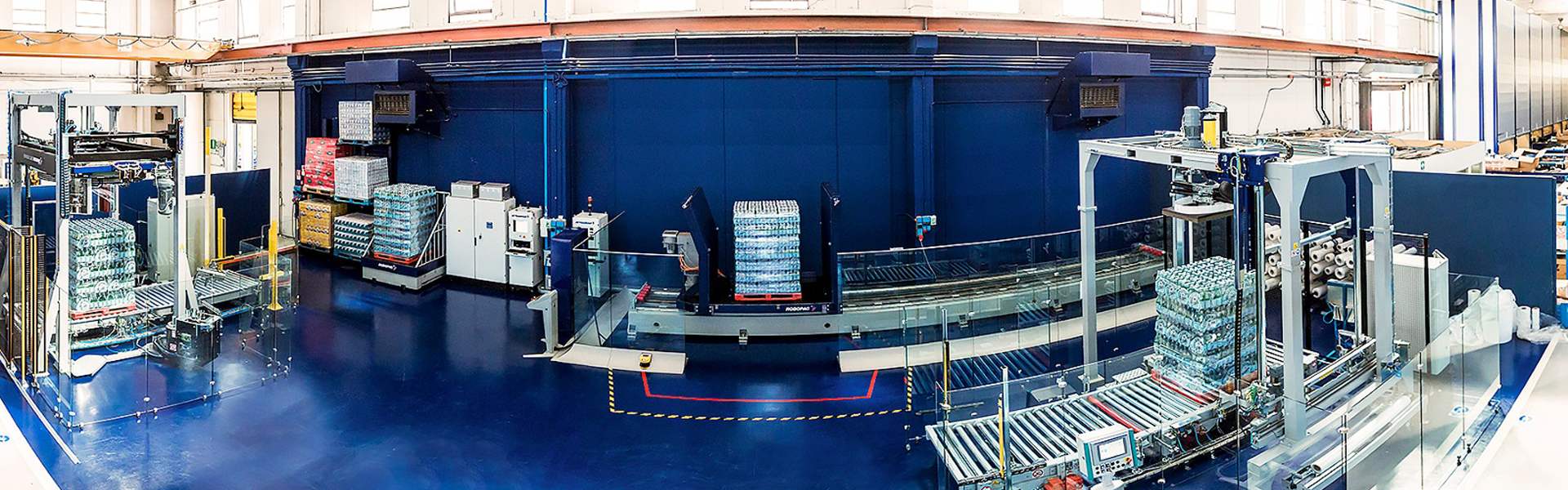

Plate UHT sterilization equipment is designed for continuous sterilization of milk, juice drinks or similar products.Equipped with aseptic filling equipment can be used for the production of products with a retention period of 3 to 6 months.

Can be connected to the separator, degassing, flashing and other equipment.

The output of the equipment is mainly regulated by the flow controller in the feed system.

Because the heating and cooling of the product are carried out in the heat recovery part of the plate heat exchanger, the heat recovery rate can be up to more than 90%.

Automatic configuration: advanced computer program control technology is adopted to control the whole process of production and operation according to the set process requirements. The CIP cleaning program is provided for automatic cleaning.

Semi-automatic configuration: the whole process of operation and operation is semi-automatic control, the operator can control the pump and reflux function from the control panel, and the temperature automatic controller to maintain the sterilization temperature.

The sterilization temperature is recorded continuously on the recorder.

Suitable for: milk, juice, tea beverage, soybean milk, milk beverage.

Equipped with electric heating unit: suitable for small production scale.

Fresh soya-bean milk

Technology: 65 ℃ homogeneous - 120 ℃ for 30 s - 5 ℃

Cooling water is 25 ℃ |