- RO water treatment equipment

- Fruit and vegetable cleaning equipment

- To nuclear, crushing equipment

- Preheat, inactivate enzyme equipment

- Beating and pressing equipment

- Beverage pre-processing and blending equipment

- CIP cleaning system

- UHT tube sterilization equipment, plate sterilization

- Empty tank decanting, solid tank stacker

- Filling and sealing machine (without gas)

- Beer can filling and sealing machine

- Thick sauce filling and sealing machine series

- Automatic PET filling and capping machine

- PE filling machine, aluminum foil sealing machine

- Glass bottle filling and capping machine

- Liquid nitrogen filling machine, liquid nitrogen freezing tunnel

- Vacuum inspection, liquid level inspection equipment

- Sterilization pot, tunnel spray sterilization

- (granular) solid canister series

- High speed blow dryer, can oiling machine

- Automatic basket loading and unloading basket machine series

- Marking machine, labeling machine, labeling machine

- Packing machine, heat shrink film machine

- other devices

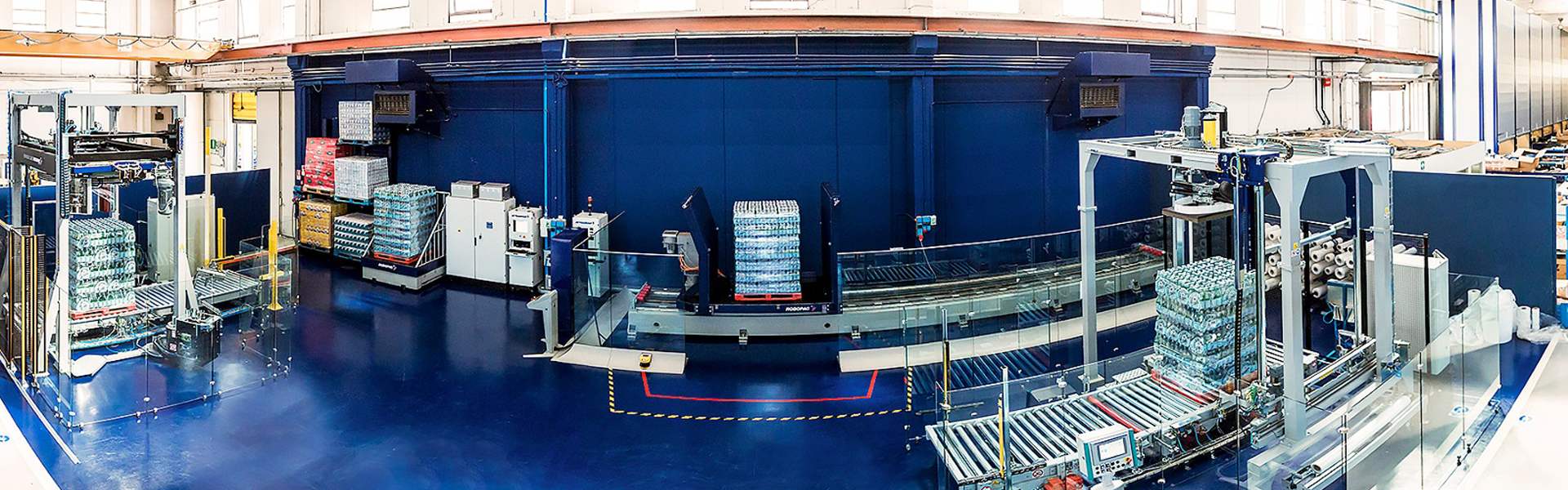

Can washer / can opener

2018-1-3 14:00:25

Main technical parameters:

Production capacity: 80-250 cans/min

Applicable tank diameter: 40-80mm

Tape speed: 0.33/ s

Matching power :0.55kw

Compressed air or vapor pressure: 0.2mpa

Inlet pressure of cleaning water: > 0.15mpa

Overall dimensions :1900 530 1150mm

Weight of equipment: 480kg

Working principle:

Is put the empty cans by turn left on the plate to the cloth belt, at the bottom of the tank by adhesive tape with a magnetic guide way with suction in the tape with adhesive tape regulated, empty cans into adhesive tape underneath a handstand, then flush pipe nozzle pressure water injection into the jar and continuous flushing, continue to operate as the tape tank into the dry period, sterile compressed air from the nozzle spray into the jar, then blow dry empty jar adhesive water (such as steam, for tank into steam fog volatile dry by adhesion and high temperature sterilization effect), then be washed empty cans with adhesive tape work, sent to the adhesive tape jar up above,

Then it is automatically transferred to the conveyor chain by the speed of the discharging pot and sent to the filling machine by the conveyor chain.