- RO water treatment equipment

- Fruit and vegetable cleaning equipment

- To nuclear, crushing equipment

- Preheat, inactivate enzyme equipment

- Beating and pressing equipment

- Beverage pre-processing and blending equipment

- CIP cleaning system

- UHT tube sterilization equipment, plate sterilization

- Empty tank decanting, solid tank stacker

- Filling and sealing machine (without gas)

- Beer can filling and sealing machine

- Thick sauce filling and sealing machine series

- Automatic PET filling and capping machine

- PE filling machine, aluminum foil sealing machine

- Glass bottle filling and capping machine

- Liquid nitrogen filling machine, liquid nitrogen freezing tunnel

- Vacuum inspection, liquid level inspection equipment

- Sterilization pot, tunnel spray sterilization

- (granular) solid canister series

- High speed blow dryer, can oiling machine

- Automatic basket loading and unloading basket machine series

- Marking machine, labeling machine, labeling machine

- Packing machine, heat shrink film machine

- other devices

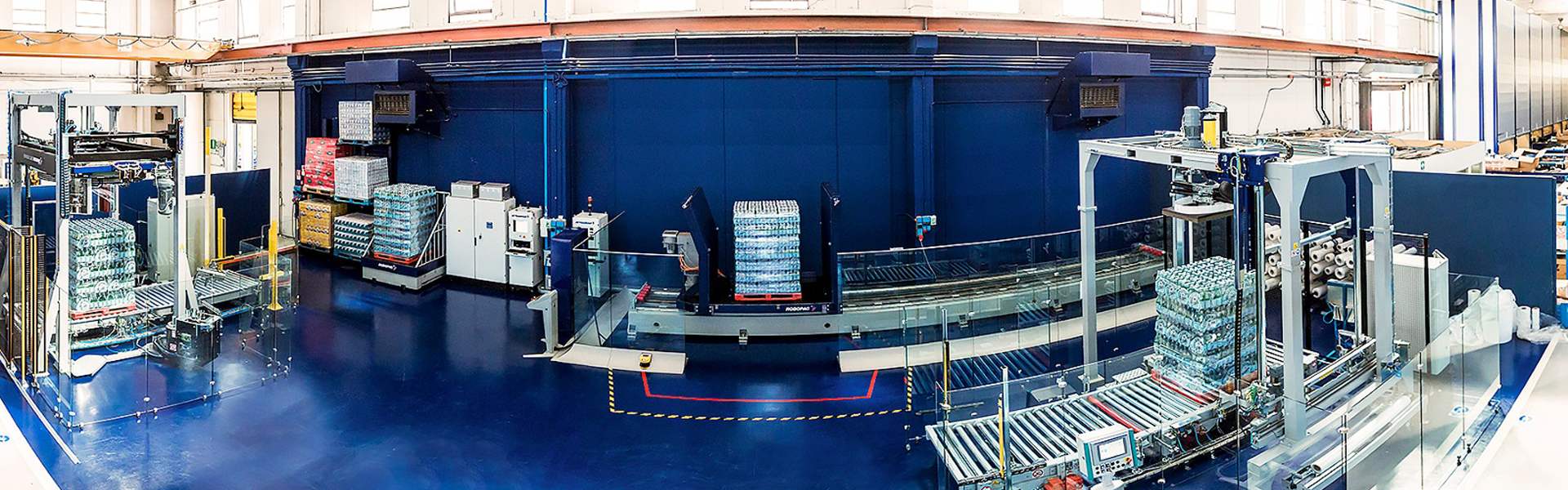

Automatic palletizing machine DP-1200

2018-2-20 16:13:45

Features:

Low stacking, starting code mode novel, high speed large capacity stacking;Improved structure, advanced transposition mode, optimized the car running track;Adopt differential method to accelerate the speed of pushing package and stacking.

Improve the operation mode of tray conveyor, reduce the time of tray conveying;It has the advantages of low cost, small volume, convenient inspection and maintenance, and high production capacity.

The new manufacturing process and technology are adopted to make the performance and appearance quality of the equipment reach the level of similar foreign products.

Control mode: PLC+ touch screen + standard control button + signal switch, automatic/manual control mode;The fault point can be found through the touch screen, easily troubleshooting;

Can be customized according to customer requirements non - standard.

Brief introduction to working principle:

The main unit of palletizer is composed of a car that can move forward and backward, a frame and a platform that can be lifted and lowered.

The lifting platform of stacker is driven by the motor to move up or down to the appropriate position. Meanwhile, the trolley moves the assembled products to the upper part of the pallet. The front and rear four shaping plates clamp the carton onto the trolley and walk backward to drop the carton onto the pallet or the carton on the upper layer.

When the yard after a stack by the stack tray conveyor discharge.

Technical parameters:

1.Model: DP - 1200

2.Stacking capacity: 1200 boxes (bags)/hour

3.Pallet size: 1200mm 1200mm 160mm

4.Air source: 0.5mpa ~ 0.6mpa

5.Air consumption: 60NM3/H

7.Power consumption: voltage 380V AC 50Hz

8.Noise: 75 db or less

9.Operation mode: touch screen