- RO water treatment equipment

- Fruit and vegetable cleaning equipment

- To nuclear, crushing equipment

- Preheat, inactivate enzyme equipment

- Beating and pressing equipment

- Beverage pre-processing and blending equipment

- CIP cleaning system

- UHT tube sterilization equipment, plate sterilization

- Empty tank decanting, solid tank stacker

- Filling and sealing machine (without gas)

- Beer can filling and sealing machine

- Thick sauce filling and sealing machine series

- Automatic PET filling and capping machine

- PE filling machine, aluminum foil sealing machine

- Glass bottle filling and capping machine

- Liquid nitrogen filling machine, liquid nitrogen freezing tunnel

- Vacuum inspection, liquid level inspection equipment

- Sterilization pot, tunnel spray sterilization

- (granular) solid canister series

- High speed blow dryer, can oiling machine

- Automatic basket loading and unloading basket machine series

- Marking machine, labeling machine, labeling machine

- Packing machine, heat shrink film machine

- other devices

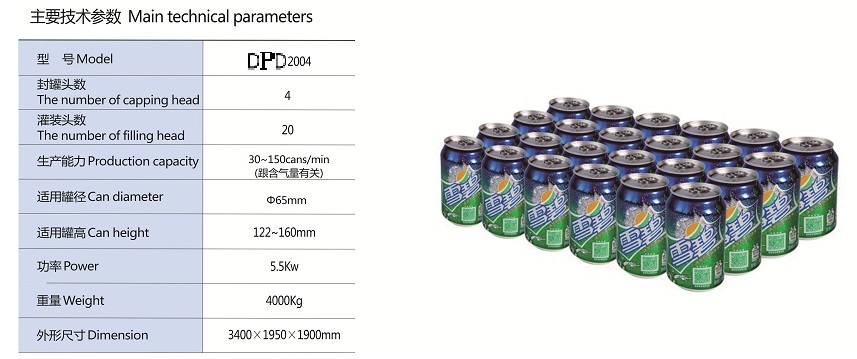

Gas filling and sealing machine DPD2004

2018-5-3 20:43:12

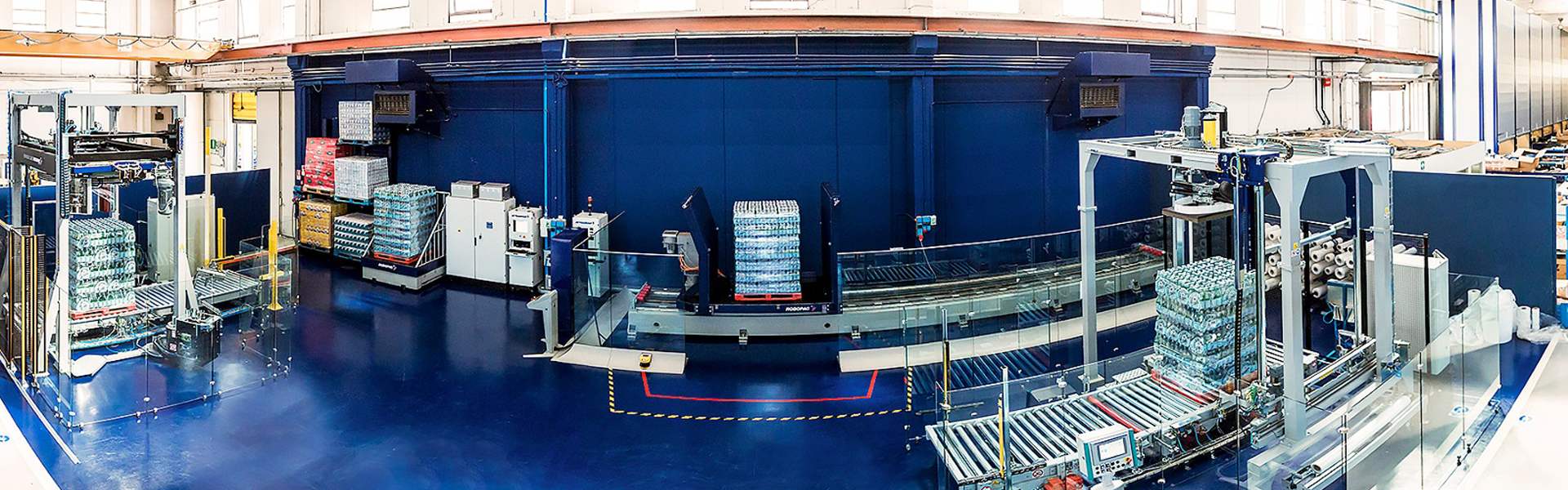

The machine is suitable for beverage cans (beer) industry non-gas cans of filling and sealing, filling and can sealing for the overall design, on the principle of isobaric filling, filling the sky tank into the pneumatic keeps up cans, compressed air is entered into the litres of tank cylinder, pneumatic triple pieces and filling valve and the rising of the empty cans of conical gasket sealing, filling valve of inversion fast block in a cylinder under the action of transfer valve open, to the empty cans aeration and formation pressure, such as beer wait from aniseed tank by 14 small pipe flow to the empty cans, empty tank liquid level to rise to block back to port, will stop filling.

After the can is out, it is sent to the sealing machine by a synchronous hook chain for sealing. When sealing, the sealing wheel is pre-sealed and then sealed. After sealing, the can is pushed out by the head of the lid mechanism and then sent out by the dialing plate to the conveyor belt.

Main electric elements adopt mitsubishi PLC, frequency converter and the proximity switch, Germany's Siemens analog output and Korea solenoid valve, designed by the company's senior electrical engineer into the most reasonable configuration form, the whole production rate can be in accordance with the requirements set by the touch screen, all common fault automatic alarm, and gives the corresponding failure reason, according to the severity of the fault, the PLC automatically determine whether the host can continue to run or stop.

The machine is characterized by fast filling speed, high consistency of liquid level in the tank to the top of the tank after filling, stable operation, good sealing quality, beautiful appearance and easy maintenance.