- RO water treatment equipment

- Fruit and vegetable cleaning equipment

- To nuclear, crushing equipment

- Preheat, inactivate enzyme equipment

- Beating and pressing equipment

- Beverage pre-processing and blending equipment

- CIP cleaning system

- UHT tube sterilization equipment, plate sterilization

- Empty tank decanting, solid tank stacker

- Filling and sealing machine (without gas)

- Beer can filling and sealing machine

- Thick sauce filling and sealing machine series

- Automatic PET filling and capping machine

- PE filling machine, aluminum foil sealing machine

- Glass bottle filling and capping machine

- Liquid nitrogen filling machine, liquid nitrogen freezing tunnel

- Vacuum inspection, liquid level inspection equipment

- Sterilization pot, tunnel spray sterilization

- (granular) solid canister series

- High speed blow dryer, can oiling machine

- Automatic basket loading and unloading basket machine series

- Marking machine, labeling machine, labeling machine

- Packing machine, heat shrink film machine

- other devices

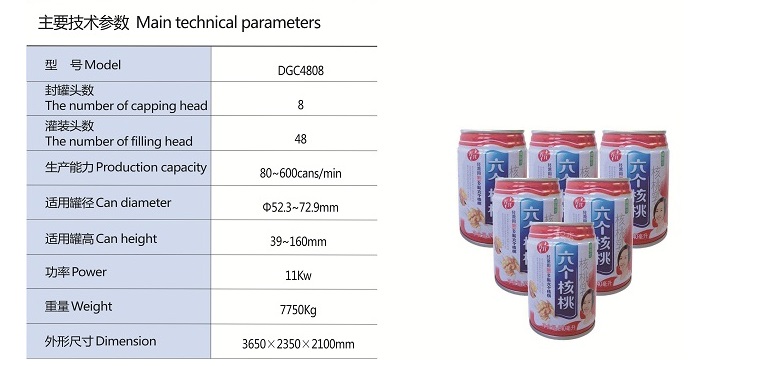

Filling and sealing machine DPC4808

2018-5-3 22:06:25

This machine is developed on the basis of digesting and absorbing domestic and foreign (excluding steam) can filling and sealing machine (sealing machine).

According to the normal pressure filling principle, when the empty tank enters into the lifting tray via the idler, the filling valve is aligned with the empty tank. The empty tank is raised and sealed, and the valve mouth of the filling valve is automatically opened. When the filling liquid level is blocked by the valve's return pipe mouth, the filling is stopped.

The filled pot is sent to the head of the sealing machine through the hook chain, and the lid is sent to the top of the pot through the cap feeder and the pressure head. When the supporting mechanism is raised, the pressure head is pressed on the top of the pot, and the sealing wheel is pre-sealed and then sealed.

Main electric elements adopt Germany's Siemens PLC, da converter and omron close to switch, Germany's Siemens analog output and Korea solenoid valve, designed by the company's senior electrical engineer into the most reasonable configuration form, the whole production rate can be in accordance with the requirements set by the touch screen, all common fault automatic alarm, and gives the corresponding failure reason, according to the severity of the fault, the PLC automatically determine whether the host can continue to run or stop.

The machine is characterized by fast filling speed, high consistency of liquid level in the tank to the top of the tank after filling, stable operation, good sealing quality, beautiful appearance and easy maintenance