- RO water treatment equipment

- Fruit and vegetable cleaning equipment

- To nuclear, crushing equipment

- Preheat, inactivate enzyme equipment

- Beating and pressing equipment

- Beverage pre-processing and blending equipment

- CIP cleaning system

- UHT tube sterilization equipment, plate sterilization

- Empty tank decanting, solid tank stacker

- Filling and sealing machine (without gas)

- Beer can filling and sealing machine

- Thick sauce filling and sealing machine series

- Automatic PET filling and capping machine

- PE filling machine, aluminum foil sealing machine

- Glass bottle filling and capping machine

- Liquid nitrogen filling machine, liquid nitrogen freezing tunnel

- Vacuum inspection, liquid level inspection equipment

- Sterilization pot, tunnel spray sterilization

- (granular) solid canister series

- High speed blow dryer, can oiling machine

- Automatic basket loading and unloading basket machine series

- Marking machine, labeling machine, labeling machine

- Packing machine, heat shrink film machine

- other devices

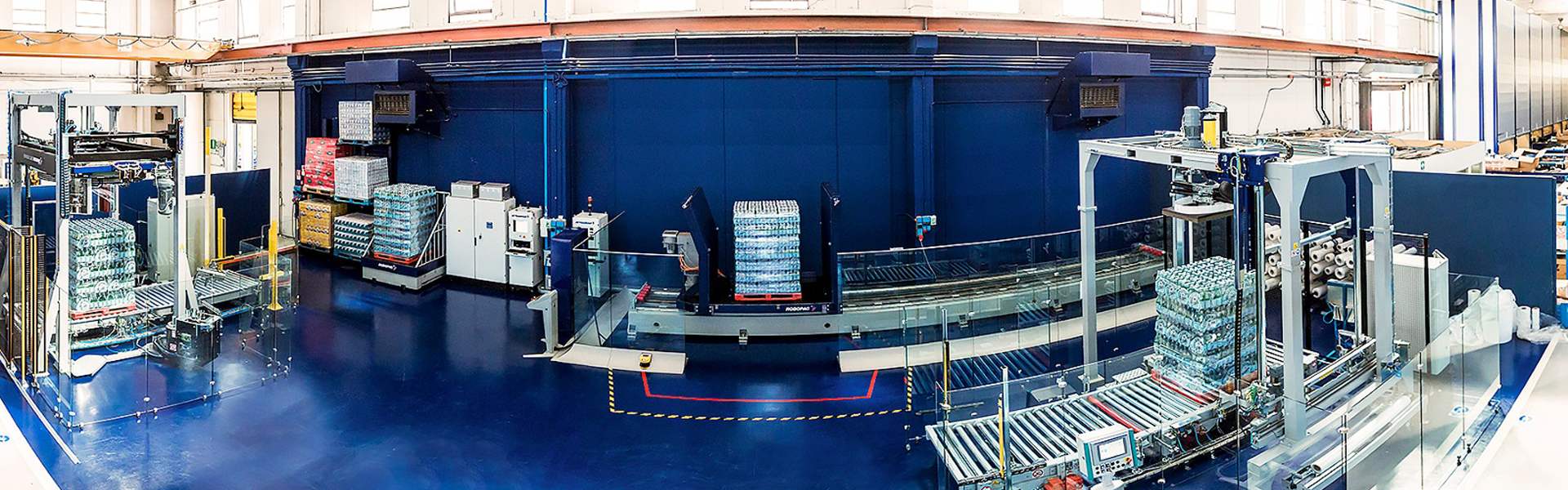

Filling aluminum foil sealing machine DPLP series

2018-5-3 23:06:34

Product details

This machine is used to produce animal and plant protein drinks such as milk, lactic acid bacteria, soy milk, etc., the whole process adopts negative pressure filling, automatic capping, electric heating sealing or high-frequency sealing (optional).

The filling forms are the bottom of the bottle and the mouth of the bottle.

It has the characteristics of fast speed, high degree of automation, stable operation and high filling precision.

Filling aluminum foil sealing machine

Filling aluminum foil sealing machine is mainly used for the filling and sealing of drinks containing pulp.

Can realize the whole process of automation, mostly used for polyester bottles, glass bottles, new materials bottles.

Filling aluminum foil sealing machine is characterized by the second filling of pulp beverage, first filling the pulp in the juice.

Firstly, dilute the pulp with a reasonable and even proportion, and then put it into the filling cylinder.

After quantitative filling into the bottle, it can be introduced into the next filling and filling juice through the star wheel.

Filling aluminum foil sealing machine structure composition:

Frame and protective opening

This part is the support of the whole machine, with enough strength and stability, the table and protective door is made of stainless steel.

The sealing system

The filling machine is mainly composed of aluminum ring sealing and sealing copper parts and bottle holder figure CAM lifting mechanism.

The transmission system

Including motor, reducer, star wheel shaft, sealing system support, secondary filling system, system spindle.

Juice filling system

This part mainly includes filling cylinder, filling valve, bottle holder and CAM lifting mechanism.

In addition, the filling valve is quantitative filling.

The filling valve is made of 304 stainless steel. The seal is made of 3 yuan and 1 c. The spring is made of special stainless steel.

Conveying system

The system includes star wheel, star wheel, the middle star wheel, out of the bottle and bottle plate and other parts.

Pulp filling system

The pulp filling system mainly includes filling cylinder and agitator, bottle holder, filling valve and figure CAM lifting mechanism.

Main Technical specification

| Model | Capacity |

|

Power | Size |

| DPL18/18/12 | 6000B/H | Bottleneck | 2.2 | 2.8 × 1.65 × 2.4 |

| DPL20/24/14 | 8000B/H | 50-110mm | 2.2 | 3.2 × 1.55 × 2.4 |

| DPL24/32/20 | 12000B/H |

|

4 | 3.6 × 2.1 × 2.4 |

| DPL32/40/32 | 15000B/H | 110-280mm | 4 | 4.65 × 2.7 × 2.4 |

| DPL40/48/36 | 18000B/H | 4 | 6.2 × 3.0 × 2.4 |