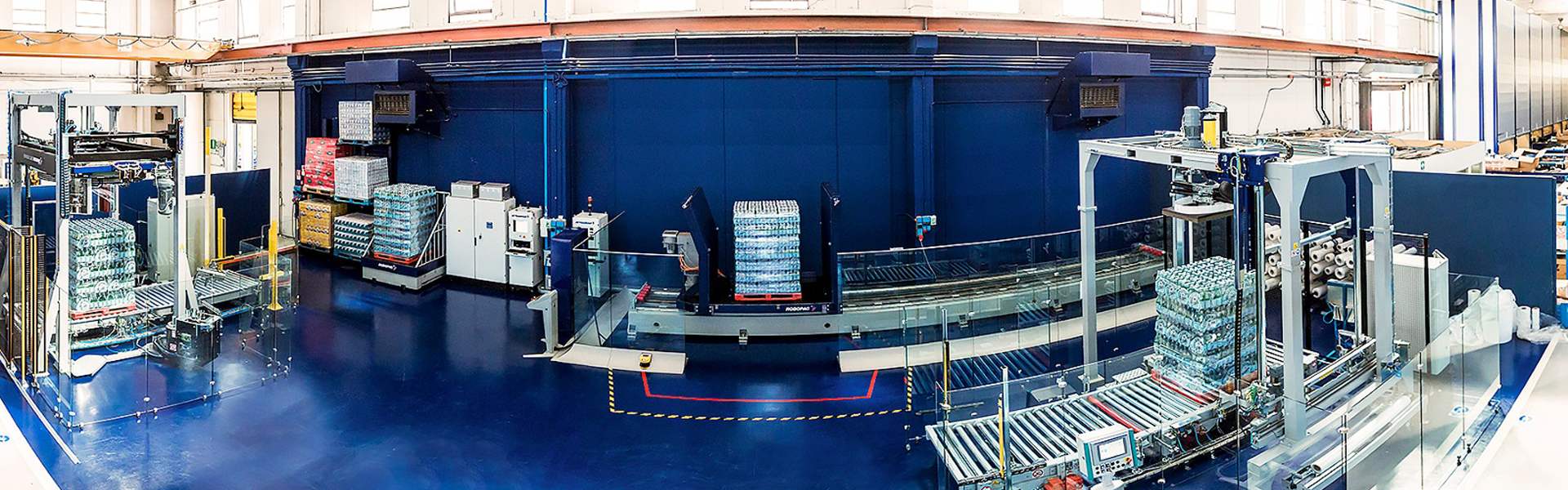

- RO water treatment equipment

- Fruit and vegetable cleaning equipment

- To nuclear, crushing equipment

- Preheat, inactivate enzyme equipment

- Beating and pressing equipment

- Beverage pre-processing and blending equipment

- CIP cleaning system

- UHT tube sterilization equipment, plate sterilization

- Empty tank decanting, solid tank stacker

- Filling and sealing machine (without gas)

- Beer can filling and sealing machine

- Thick sauce filling and sealing machine series

- Automatic PET filling and capping machine

- PE filling machine, aluminum foil sealing machine

- Glass bottle filling and capping machine

- Liquid nitrogen filling machine, liquid nitrogen freezing tunnel

- Vacuum inspection, liquid level inspection equipment

- Sterilization pot, tunnel spray sterilization

- (granular) solid canister series

- High speed blow dryer, can oiling machine

- Automatic basket loading and unloading basket machine series

- Marking machine, labeling machine, labeling machine

- Packing machine, heat shrink film machine

- other devices

Vacuum pressure detector

2018-5-4 9:56:07

My company produces vacuum tester whose basic principle is: if the tank (bottle) vacuum degree is different, in the body cause the tank lid (bottle) is different also, the shape of the deformation of the machine precision components for testing tiny deformation of the lid, the data after the computer automatic processing, immediately analyze whether the products meet the requirements of vacuum, the vacuum did not meet the product immediately launched by the cylinder behind the conveyor line, so the device can carry on the dynamic on-line detection on the conveyor belt, and automatically picking after test did not reach the set of "vacuum" or "inner pressure tank (bottle).

This machine is suitable for two pieces of aluminum cans, three pieces of iron cans, glass bottles and all other cladding containers, with simple and efficient operation.

1.1 application features:

1. It is suitable for vacuum testing of the inner pot of the same sealing machine production line. Different sealing machines can't be mixed together for testing, because the sealing datum level of different machines is very different.

2. Small error, good repeatability, if it is necessary to change the tank shape, adjustment is very easy.

3. Precision infrared positioning system, 500 containers per minute (high-speed type) and 300 containers per minute (ordinary type) or less, and 5,133 cans or more.

4. All containers, whether iron, aluminum, glass, aluminum and platinum seals or plastic containers, can be inspected as long as the mouth diameter is above 50 mm.

5. As long as 50 ℃ temperature stability of the following are detectable.

6. The length of the conveyor belt is only 50cm.

1.2 main parameters

The range of the tank diameter: Φ 52-105 - mm

Applicable tank height: 39 ~ 133mm

Production capacity: 0 ~ 500 cans/min

Weight: 40 kg

Overall dimension:

controller: 400 350 800mm detection component: 380 250 280mm

,working principle

Lord if vacuum in tank (bottle), cause the tank lid (bottle) is different also, the shape of the deformation of the machine with the lid of a precision components detection of tiny deformation, the data after the computer automatic processing, immediately analyze whether the products meet the requirements of vacuum, the vacuum did not meet the product immediately launched by the cylinder behind the conveyor line, so the device can carry on the dynamic on-line detection on the conveyor belt, and automatically picking after test did not reach the set of "vacuum" or "inner pressure tank (bottle).