- RO water treatment equipment

- Fruit and vegetable cleaning equipment

- To nuclear, crushing equipment

- Preheat, inactivate enzyme equipment

- Beating and pressing equipment

- Beverage pre-processing and blending equipment

- CIP cleaning system

- UHT tube sterilization equipment, plate sterilization

- Empty tank decanting, solid tank stacker

- Filling and sealing machine (without gas)

- Beer can filling and sealing machine

- Thick sauce filling and sealing machine series

- Automatic PET filling and capping machine

- PE filling machine, aluminum foil sealing machine

- Glass bottle filling and capping machine

- Liquid nitrogen filling machine, liquid nitrogen freezing tunnel

- Vacuum inspection, liquid level inspection equipment

- Sterilization pot, tunnel spray sterilization

- (granular) solid canister series

- High speed blow dryer, can oiling machine

- Automatic basket loading and unloading basket machine series

- Marking machine, labeling machine, labeling machine

- Packing machine, heat shrink film machine

- other devices

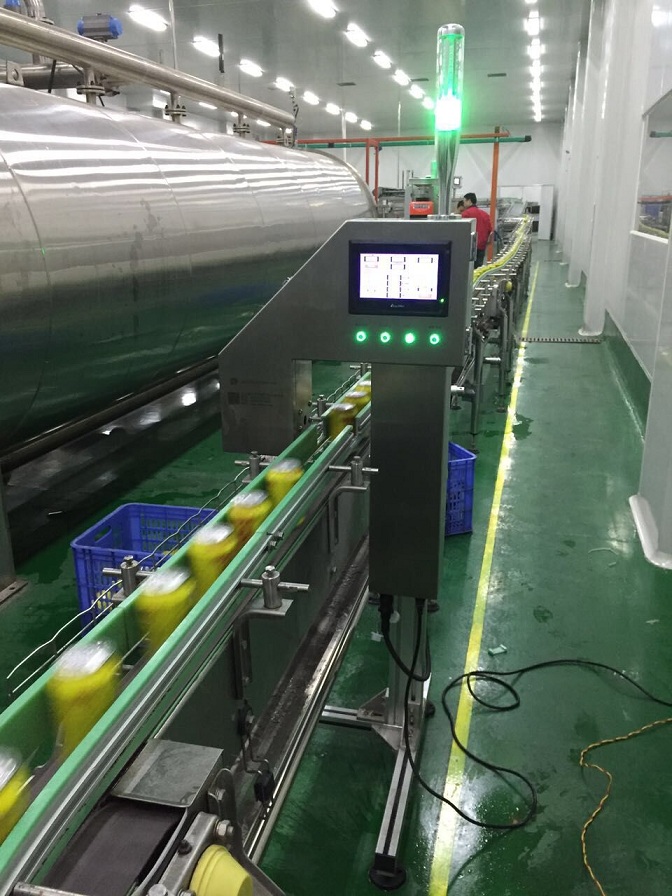

X-ray on-line liquid level detector

2018-5-4 10:04:04

DPW600 filling liquid level detector is a kind of advanced level liquid level detector developed and produced by our company.By using the principle that the intensity of ray changes with the position of the material surface after the interaction between the low-energy photon source and the material under test, the filling liquid material capacity can be controlled.Because of its non-contact measurement method, it fundamentally solves the problem that the conventional weighing method cannot measure the filling liquid material capacity on the production line.Therefore widely used in food, medicine, chemical industry, weapons **** and other filling (whether bottled or canned) liquid material line online automatic control.

Functional description

Application: two - piece can, three - piece can, PET bottle, glass bottle, etc

1. Technical features

Non-contact detection, fast detection speed, high accuracy.

Can automatically adapt to different production line speed, dynamic detection

Stainless steel shell, host seal design and manufacture, anti-fog steam, waterproof drops, strong environmental adaptability.

In idle time, it automatically blocks the emission of high-frequency rays

The use of hardware circuit, the use of embedded operating system, to ensure long-term stable operation

Sound and light alarm at the same time, and automatically remove unqualified containers.

Use 7-inch display touch screen, provide a simple and reliable man-machine interface, change the bottle flexible

Large screen Chinese display, LED backlit LCD, clear and bright writing, man-machine dialogue operation.

Does not contain the isotope radioactive source, USES the soft ray design, the ray protection is safe and reliable.

High cost performance

2. Main technical indicators

Linear speed of conveyor belt in production line: 1.8m/s.50mm tank diameter maximum detection speed up to 1200 cans/min

Container diameter: 20mm ~ 100mm.(different container material density and diameter, different device selection)

Dynamic container resolution: 2mm.(foam and sloshing will affect the detection accuracy)

Static measuring liquid level accuracy: 0.5mm(water)

8-hour static measurement stability: 0.15mm(water)

Reject rate of unqualified containers: 99% (detection speed up to 1200 / min).

Bring the temperature error: within the scope of the 0 ℃ to 40 ℃, relative to the measured value of the 20 ℃ temperature error is 0.25 mm or less

Work requirements: the minimum time width of a can without a can is 10ms, and the conveyor belt must be stable (the smoothness determines the accuracy).

Bring about the use of the environment: the temperature 0 ℃ to 40 ℃, relative humidity is not more than 95%, the power supply: 220 v + 20 v, 50 hz

Power consumption: 150W

Size: length width height: 530mm 150mm 350mm