- RO water treatment equipment

- Fruit and vegetable cleaning equipment

- To nuclear, crushing equipment

- Preheat, inactivate enzyme equipment

- Beating and pressing equipment

- Beverage pre-processing and blending equipment

- CIP cleaning system

- UHT tube sterilization equipment, plate sterilization

- Empty tank decanting, solid tank stacker

- Filling and sealing machine (without gas)

- Beer can filling and sealing machine

- Thick sauce filling and sealing machine series

- Automatic PET filling and capping machine

- PE filling machine, aluminum foil sealing machine

- Glass bottle filling and capping machine

- Liquid nitrogen filling machine, liquid nitrogen freezing tunnel

- Vacuum inspection, liquid level inspection equipment

- Sterilization pot, tunnel spray sterilization

- (granular) solid canister series

- High speed blow dryer, can oiling machine

- Automatic basket loading and unloading basket machine series

- Marking machine, labeling machine, labeling machine

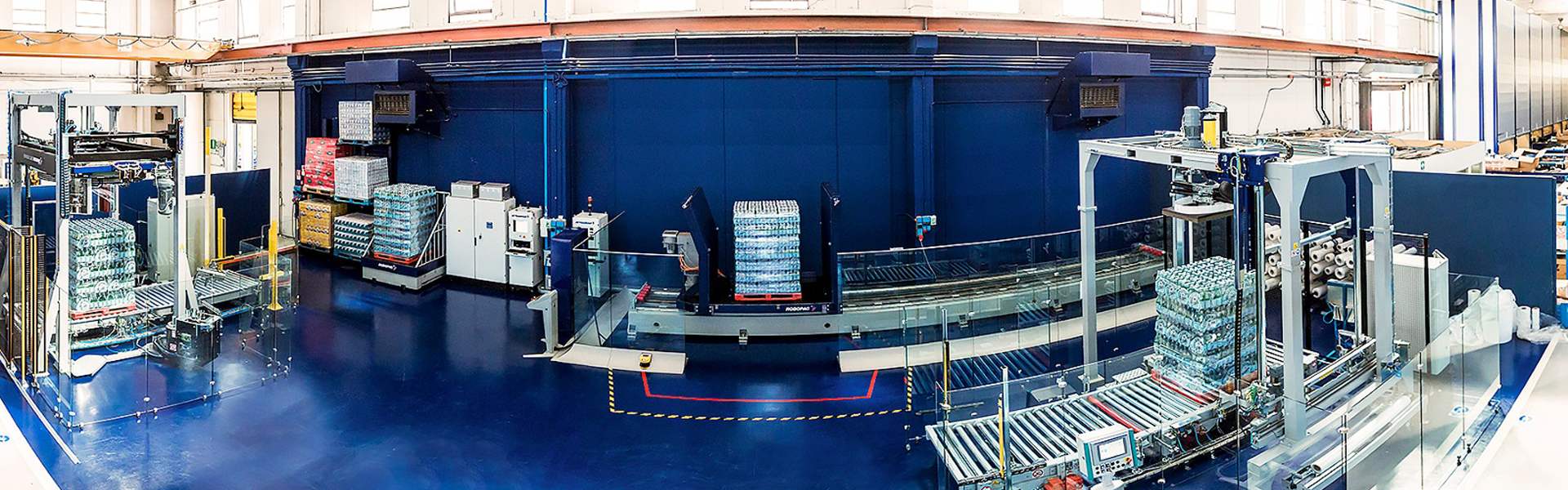

- Packing machine, heat shrink film machine

- other devices

Cooking Jacked Kettle

2018-5-4 11:04:15

Stainless Steel Jacketed Kettle is also named vertical steam heating double-layer cauldron. Usually composed of pot and hold feet, and the pot is the double layer structure formed by inside and outside spherical pot; middle layer can add steam to steam. It has characteristics such as big heating area, high thermal efficiency, uniform heating, short boiling time, easy control of the heating temperature etc. Not only has good-appearance, but also easy to install and operate. It is safe and convenient. Now it has been widely applied in food processing. Some large restaurants and canteens also use it to boil soup, cook, stew and porridge. It is considered to be the ideal equipment in the area of improving quality, shortening the time and improving working conditions.

Usage of Jacketed Kettle

Characteristics of Jacketed Kettle

Technical parameters of Jacketed Kettle

Model 50 100 200 300 400 500 600 800 1000

Caliber(mm) Φ600 Φ700 Φ800 Φ900 Φ1000 Φ1100 Φ1200 Φ1400 Φ1500

Depth of Pot(mm) 400 450 530 630 680 730 780 830 900

Heating area(m2) 0.45 0.58 1.12 1.42 1.75 2 2.3 3.2 3.9

Boiling time(min) 5 8 11 14 18 22 25 34 40

Interface size Steam pipe 3/4” 1” 2”

Condensate pipe 3/4” 1”

Working pressure ≤0.09Mpa(can be adapted according to customers’ requirement)

Stirring speed 36 r/min(can be adapted according to customers’ requirement)

Stirring power(Kw) 0.55 0.55 0.75 1.1 1.1 1.5 1.5 2.2 2.2