- RO water treatment equipment

- Fruit and vegetable cleaning equipment

- To nuclear, crushing equipment

- Preheat, inactivate enzyme equipment

- Beating and pressing equipment

- Beverage pre-processing and blending equipment

- CIP cleaning system

- UHT tube sterilization equipment, plate sterilization

- Empty tank decanting, solid tank stacker

- Filling and sealing machine (without gas)

- Beer can filling and sealing machine

- Thick sauce filling and sealing machine series

- Automatic PET filling and capping machine

- PE filling machine, aluminum foil sealing machine

- Glass bottle filling and capping machine

- Liquid nitrogen filling machine, liquid nitrogen freezing tunnel

- Vacuum inspection, liquid level inspection equipment

- Sterilization pot, tunnel spray sterilization

- (granular) solid canister series

- High speed blow dryer, can oiling machine

- Automatic basket loading and unloading basket machine series

- Marking machine, labeling machine, labeling machine

- Packing machine, heat shrink film machine

- other devices

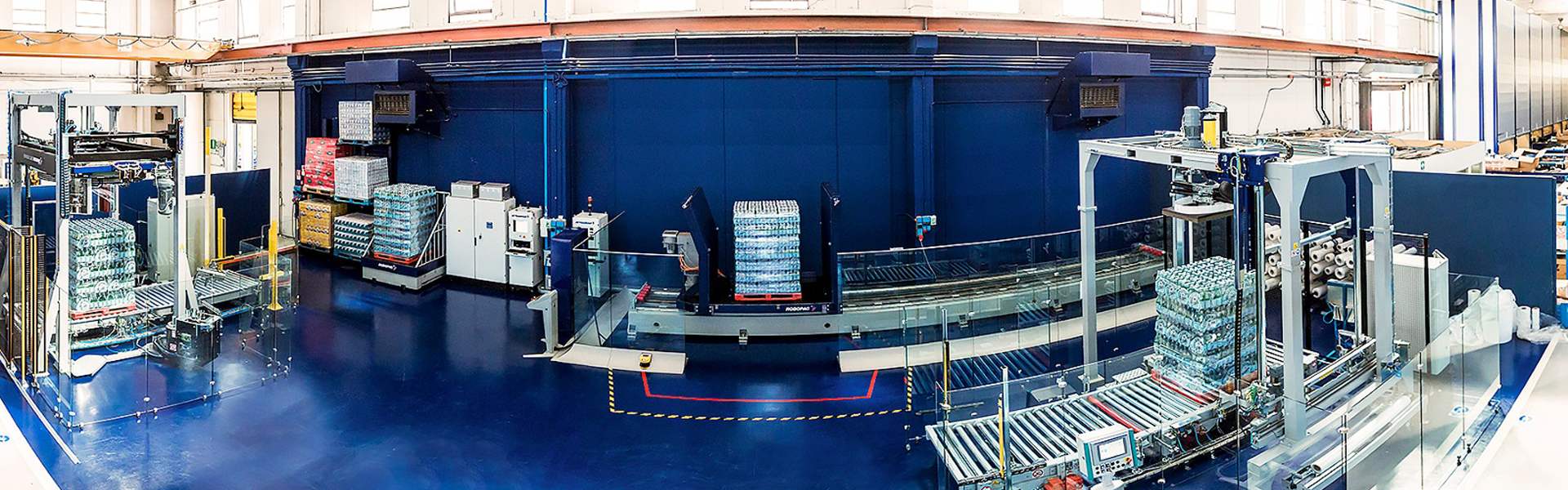

PET functional beverage filling machine

2018-5-3 22:37:56

Overview of filling equipment for energy drinks:

The filling machine is suitable for the filling and production of functional drinks, vitamin drinks, fruit juice, tea drinks and so on.

Applicable containers: PET bottles of various sizes and shapes;

Filling system for energy drinks: pressure filling;

Capacity of energy drink filling production line: 5000BPH -- 40000BPH;

The energy drink filling machine adopts the standard model of RXG series hot filling machine manufactured by deepora machinery, which is "three in one". For special production conditions, a disinfectant can be added, namely "four in one". The filling system for energy drinks fully takes into account the characteristics of beverage products (such as easy foaming of tea drinks and mixed juice drinks) and the main technical requirements for hot filling.

Technical parameters of energy drink filling machine:

• full filling, to avoid the collapse of the bottle after cooling, and to minimize the amount of dissolved oxygen.

• bin and feeding system, reasonable feeding design (constant flow, constant pressure, no foam), usually in the form of high tank feeding.

• reasonable structure of the bin system (with exhaust, full seal, temperature can be measured), in the high-speed line to cancel the large cylinder, replaced by a liquid distributor, CIP pressure cleaning can be achieved thoroughly.

• hygienic filling head system, umbrella flow structure, fast filling speed, can meet the full filling and health requirements of the filling head.

• the filling machine adopts perfect temperature control system for hot filling.

• the filling machine for energy drinks has a reflux tank system that automatically starts the material delivery.

• perfect CIP cleaning system.